Metal Roofing Sheets: Corrosion Resistance and Long-Term Durability

Galvalume® vs. Aluminum: Performance in Coastal, High-Salinity Environments

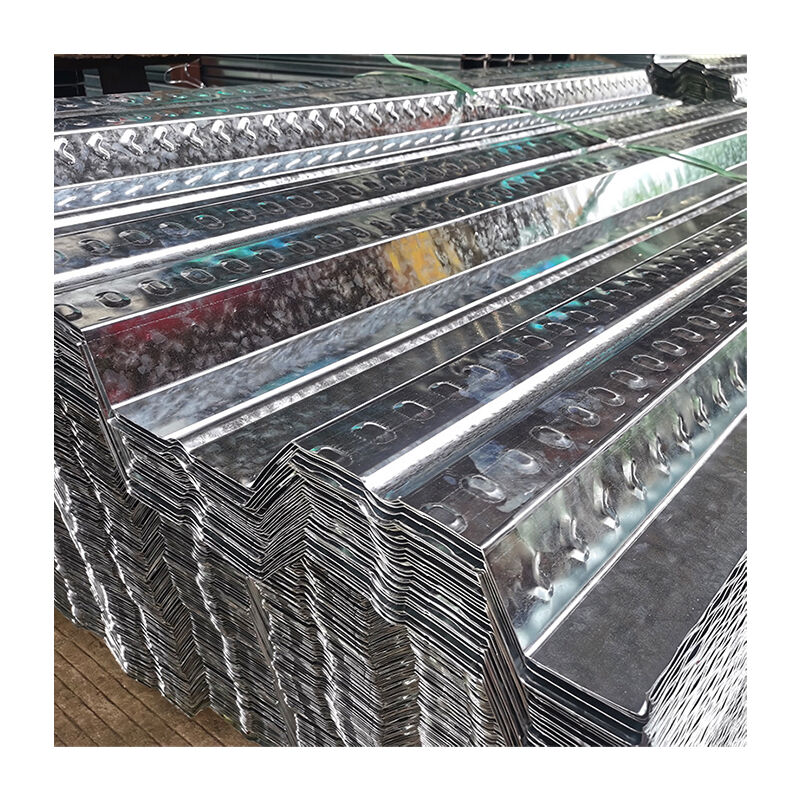

Galvalume® roofing combines aluminum, zinc, and silicon to shield steel from salt damage. When compared to regular aluminum over time in coastal areas, Galvalume shows remarkable results too. Tests indicate around 95% less rust after about ten years according to ASTM standards. Regular aluminum does create a protective layer against salt spray naturally, but when there are cuts or scratches on the surface, it doesn't offer much help. That's where Galvalume shines because its zinc content actually fights off those pesky pits that form at damaged spots, which matters a lot near the ocean. Plus, Galvalume is stiffer than aluminum, so builders often go for it in places prone to hurricanes. Aluminum tends to bend under strong winds, while Galvalume holds up better, making it safer for long-lasting buildings in stormy weather zones.

Zinc and Copper: Self-Healing Patina Formation Under UV, Rain, and Thermal Cycling

Roofing sheets made from zinc and copper naturally form these amazing self-healing patinas when exposed to the atmosphere. When it rains, zinc starts creating those tough zinc carbonate layers pretty quickly, usually within about two days according to ISO standards. These layers actually seal up tiny cracks and help restore the surface so it looks almost new again. Copper takes a different path but just as impressive. It slowly turns into that characteristic blue-green color over time through chemical reactions with sulfur compounds and oxygen. This transformation can keep copper roofs looking good for well over a century. Both metals have this remarkable ability to rebuild their protective coatings when temperatures fluctuate between really cold winter nights and hot summer days. This helps maintain strong seams and stops screws and nails from corroding in areas where freezing and thawing happen regularly. Tests show that even after being aged artificially, zinc still reflects around 90% of ultraviolet light. Meanwhile, the oxide layer on copper doesn't break down easily when faced with acidic rainfall conditions either.

Polymer-Based Roofing Sheets: UV Stability, Moisture Resistance, and Seam Integrity

Roofing sheets made from polymers rely on special synthetic blends that keep performing well even when weather gets tough. The way these materials are built gives them natural protection against UV damage without needing extra coatings. They stay flexible whether temperatures drop below freezing or climb into extreme heat ranges. Plus, their surfaces naturally repel water, which helps prevent mold growth and slows down deterioration over time. When installed properly with heat welding, the seams form solid waterproof barriers throughout the entire roof system. This makes polymer roofs particularly good for areas near coasts or places with lots of humidity, where regular materials tend to break down faster because of constant exposure to salt air and damp conditions.

PVC and Polyester Coatings: Hydrophobicity, ASTM D6754 Tensile Retention After QUV Aging

The reason PVC and polyester coatings resist water so well comes down to their molecular makeup. These materials have those non-porous, water-repelling properties that make water just bead up and slide right off instead of getting absorbed. This helps keep whatever surface they're protecting intact even when it rains for days on end. When we look at actual testing data from QUV weathering machines that simulate years worth of sunlight exposure plus all those wet-dry cycles, premium quality PVC still holds about 95% of its original tensile strength after running through 4,000 hours of this treatment according to ASTM standards mentioned in the Roofing Materials Journal back in 2023. Plus these coatings stay pretty clean too because their smooth surfaces don't let algae stick around much and they tend to gather less dirt overall which means fewer cleaning sessions needed over time.

EPDM, TPO, and Recycled Rubber: Comparative Water Absorption and Freeze-Thaw Resilience

EPDM, TPO, and recycled rubber roofing sheets differ significantly in moisture management and thermal resilience. EPDM™s vulcanized rubber structure absorbs less than 0.5% water, while TPO achieves comparable hydrophobicity through crystalline polymer arrangements. Recycled rubber variants absorb 3–5‚ more moisture due to residual porosity from source materials. In freeze-thaw testing:

- TPO retains flexibility down to 40°F by stabilizing plasticizers

- EPDM withstands over 300 cycles without cracking

- Recycled rubber shows seam deformation after just 50 cycles

These results confirm why TPO and EPDM are preferred for northern climates where repeated thermal cycling drives material fatigue (Building Enclosure Studies, 2022).

Mineral-Based Roofing Sheets: Thermal Mass, Porosity Control, and Passive Weather Defense

Clay and Concrete Tiles: Glaze Integrity, Capillary Break Design, and Low-Temperature Impact Resistance

Both clay and concrete tiles make use of their natural mineral content along with special surface treatments to offer lasting protection against bad weather conditions. The vitrified glaze forms a really effective barrier that stops water from soaking in much beyond 6%. This helps resist damage from UV rays and also protects against erosion caused by acid rain. When it comes to design, these tiles have interlocking shapes and specially made underlayers that stop water from moving sideways through tiny gaps. Even when heavy winds drive rain horizontally across surfaces, saturation remains minimal. Another great feature is their ability to absorb heat and release it slowly, which means they don't expand and contract as dramatically with temperature changes. According to standard testing (ASTM C67-23), concrete tiles can survive over 60 freeze-thaw cycles without showing cracks. That makes them particularly good for colder regions where other materials tend to fail after repeated exposure to freezing temperatures. With their low water absorption rate, clever water management system, and strong construction, these tiles stand up well against harsh weather for many years to come.

FAQ

What are the benefits of Galvalume over aluminum in coastal environments?

Galvalume offers superior resistance to rust and damage from salt due to its zinc content, especially on scratched or damaged surfaces. It is also stiffer, making it preferable in hurricane-prone areas compared to aluminum.

How do zinc and copper roofing sheets self-heal?

Zinc forms protective zinc carbonate layers when it rains, sealing cracks. Copper turns blue-green over time through chemical reactions, contributing to its durability and self-healing properties.

Are polymer-based roofing sheets suitable for extreme temperatures?

Yes, polymer roofing sheets remain flexible in both low and high temperatures, providing natural UV protection and water repellence, making them ideal for various climates.

How do PVC and polyester coatings achieve water resistance?

Their non-porous molecular structure allows water to bead and slide off easily, maintaining surface integrity even after prolonged exposure to water and sunlight.

Why are TPO and EPDM preferred in northern climates?

TPO retains flexibility at very low temperatures, while EPDM withstands numerous freeze-thaw cycles without cracking, making them highly durable in cold climates.

Table of Contents

- Metal Roofing Sheets: Corrosion Resistance and Long-Term Durability

- Polymer-Based Roofing Sheets: UV Stability, Moisture Resistance, and Seam Integrity

- Mineral-Based Roofing Sheets: Thermal Mass, Porosity Control, and Passive Weather Defense

-

FAQ

- What are the benefits of Galvalume over aluminum in coastal environments?

- How do zinc and copper roofing sheets self-heal?

- Are polymer-based roofing sheets suitable for extreme temperatures?

- How do PVC and polyester coatings achieve water resistance?

- Why are TPO and EPDM preferred in northern climates?