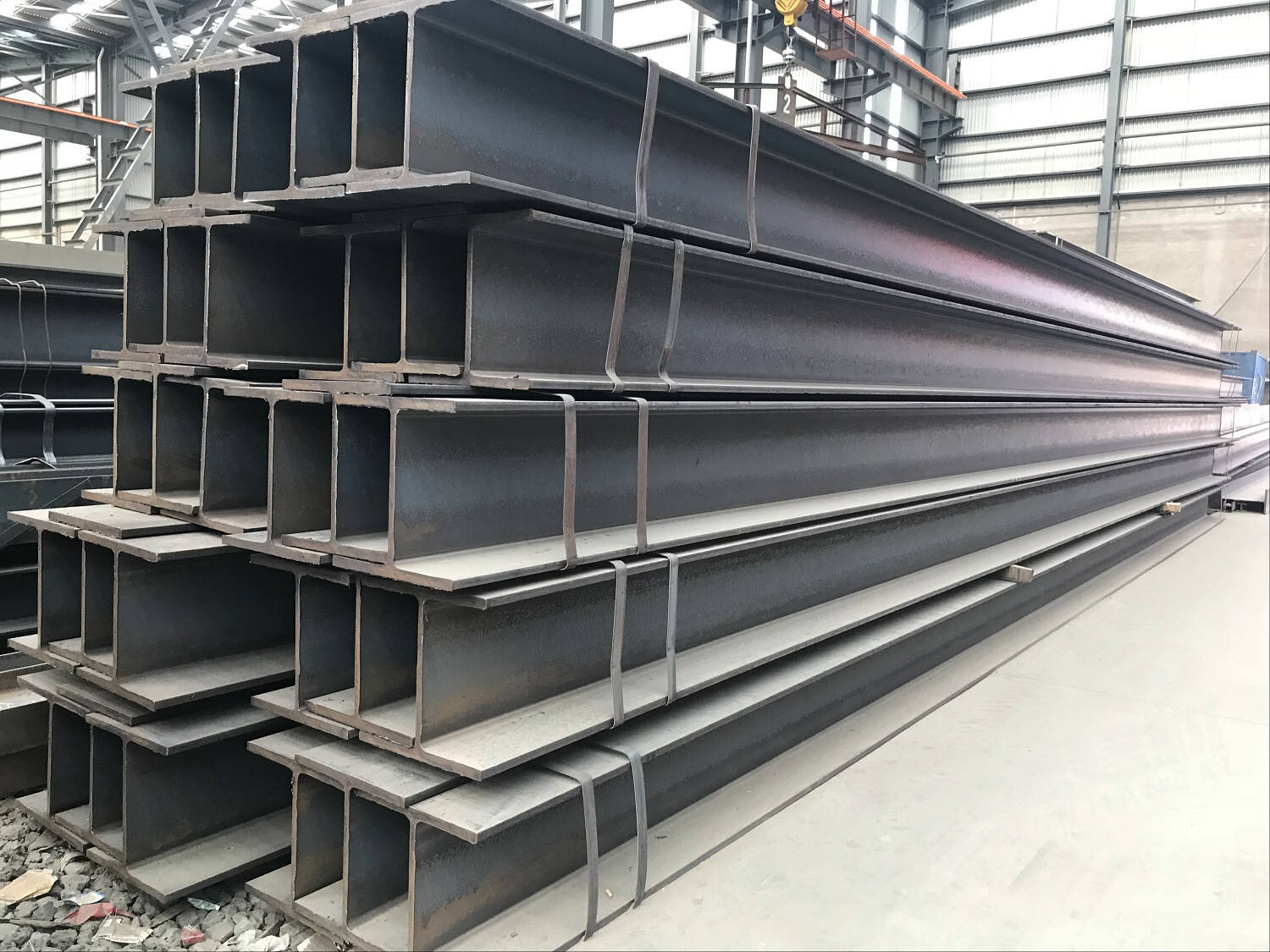

Hot rolled steel is a widely used material produced by rolling steel at high temperatures (above recrystallization point), resulting in a rough surface and excellent formability, and Songchen Steel Co., Ltd, with over 20 years of experience, is a leading supplier of hot rolled steel products for global markets. Songchen’s hot rolled steel includes coils, plates, and sheets, available in various grades such as carbon steel, alloy steel, and structural steel, designed for applications like construction beams, automotive parts, and industrial machinery. The hot rolling process imparts strength and ductility, making hot rolled steel suitable for welding and bending, while its cost-effectiveness appeals to large-scale projects in South America, Southeast Asia, the Middle East, and Africa. With a storage area of over 50,000 square meters, Songchen maintains ample stock of hot rolled steel to ensure quick delivery, supporting clients with timely supply. Backed by strict quality control, hot rolled steel from Songchen Steel Co., Ltd meets international standards, ensuring consistency and performance, solidifying the company’s position as a reliable provider of hot rolled steel solutions.